The ProTech Venturi Steam Trap

Orifice plate technology was developed in the 1960’s by the U.S. Navy. The use of orifice plates to replace a ship’s mechanical steam traps proved to significantly reduce failures while dramatically improving the steam system efficiency. Today orifice plates like these are typically referred to as orifice steam traps.

Orifice plates have been traditionally relied on for condensate removal when dependability is paramount. One such application is on steam turbines where a steam trap failure would be catastrophic.

The ProTech steam trap replacement device utilizes an evolved venturi nozzle to serve the function of the orifice plate.

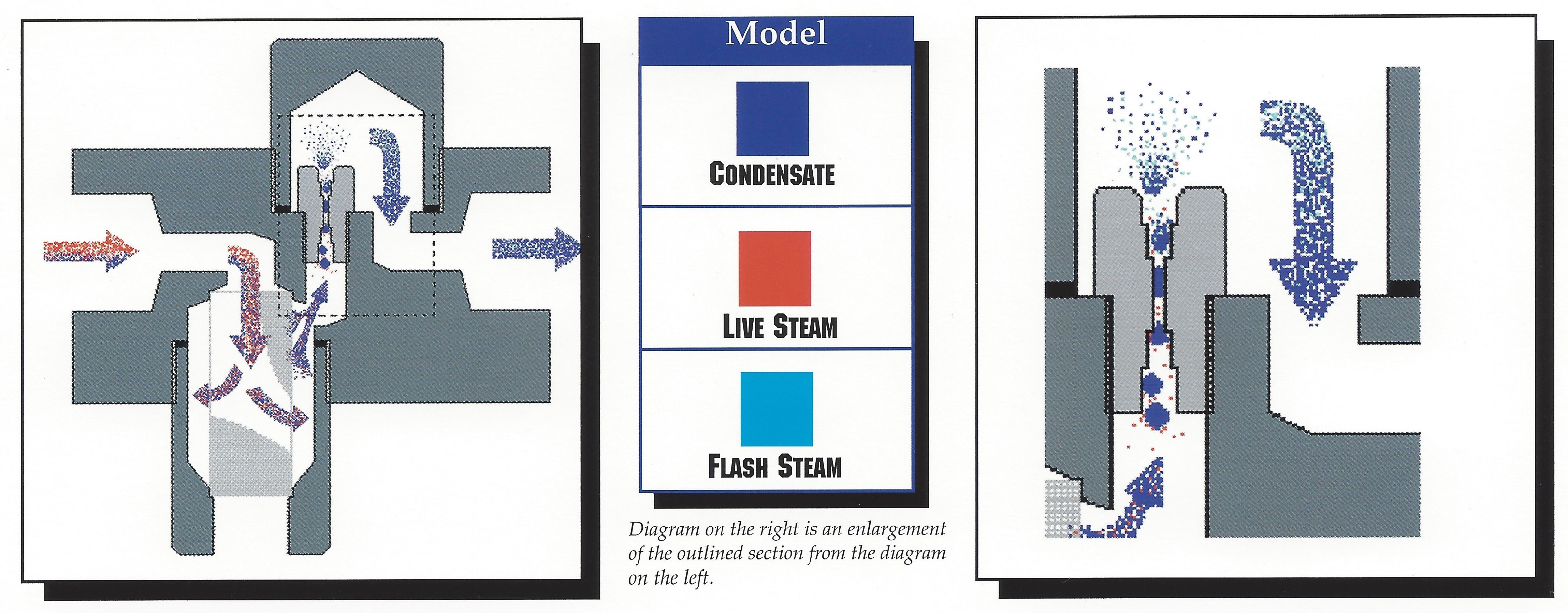

Both the orifice plate and the advanced venturi nozzle serve as an efficient condensate removal device (steam trap) by taking advantage of the significant physical differences (specific volume) between steam and condensate. For example, at 50 psia, steam has a specific volume 500 times greater than that of condensate. The theory of two-phase flow explains condensate’s disruptive impact on the flow of steam. The condensate, denser and traveling at much slower speeds than live steam, occupies the orifice or venturi nozzle and impedes the passage of steam. As condensate exits the diverging section of the venturi nozzle, a portion will flash, resulting in a significant increase in specific volume thus creating a choking effect which further inhibits the passage of live steam.

We are proud of the relationships we have developed.

View a partial client list here.

Questions? Call Us Today

843-681-5157

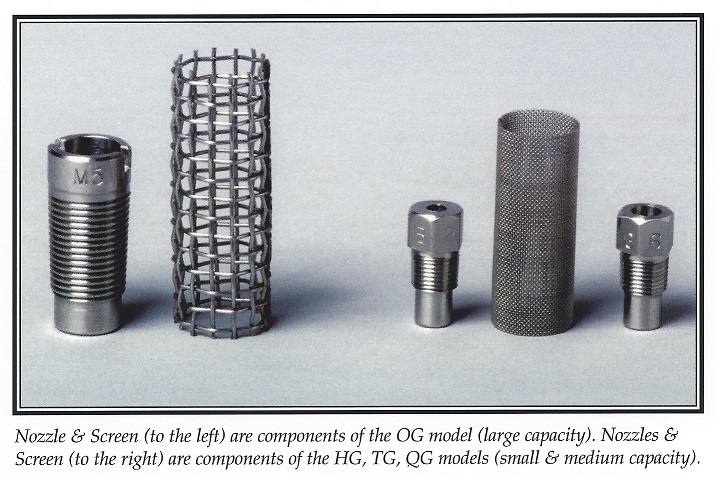

The ProTech venturi steam trap replacement device utilizes an in-line removable venturi nozzle. The nozzle is protected from debris by an integral strainer.

Advantages of a Removable Venturi Nozzle:

- Easily removed to inspect/clean

- Easily swapped to change trap capacity

- Converging nozzle inlet results in increased condensate capacity

- Diverging nozzle discharge allows condensate to flash, creating a local back pressure, restricting the passage of live steam

- The simplicity of the ProTech design results in unparalleled reliability

Testing, in accordance with ANSI/ASME PTC 39.1 1980, has shown the ProTech device to be more efficient than properly operating mechanical traps (U.S. Dept. of Energy Study).

It is quickly becoming the preferred steam trap for progressive, efficiency minded, industrial and commercial institutions.

The Proficient Technologies ProTech Venturi Steam Trap is proudly manufactured in the U.S.A. and comes with a standard 20-year guarantee.

The ProTech saves you money because it:

- CANNOT FAIL IN THE OPEN POSITION, thus preventing energy waste and protecting your system.

- Restores condensate back pressure and temperature to design levels

- Eliminates water hammer

- Doesn’t back up condensate before discharging, therefore:

- reducing the formation of carbonic acid and resulting pipe deterioration

- maximizing heat transfer surface area which increases equipment productivity

- Automatically vents air and non-condensables

- Freeze protected

- SIGNIFICANTLY REDUCES MAINTENANCE COSTS

The ProTech Venturi Steam Trap (cut sheet) cannot fail in the open position because there are no moving parts to wear or fail so, unlike other steam traps, ITS EFFICIENCY DOES NOT DETERIORATE WITH TIME. Other important features:

- The nozzle is specifically engineered for the application.

- The nozzle can be removed, inspected, cleaned, and replaced without disconnecting the steam trap from the piping.

- It has an integral strainer that can be removed, inspected, cleaned and replaced without disconnecting the steam trap from the piping.

- It can be installed horizontally or vertically.

- It has a life expectancy of 20++ years.

Answers to common questions about the ProTech venturi steam trap replacement device can be found on the “FAQ” page. Better yet, give us a call. We look forward to speaking with you and learning more about your needs.