The ProTech Venturi Steam Trap

Orifice plate technology was developed in the 1960’s by the U.S. Navy. The use of orifice plates to replace a ship’s mechanical steam traps proved to significantly reduce failures while dramatically improving the steam system efficiency. Today orifice plates like these are typically referred to as orifice steam traps.

Orifice plates have been traditionally relied on for condensate removal when dependability is paramount. One such application is on steam turbines where a steam trap failure would be catastrophic.

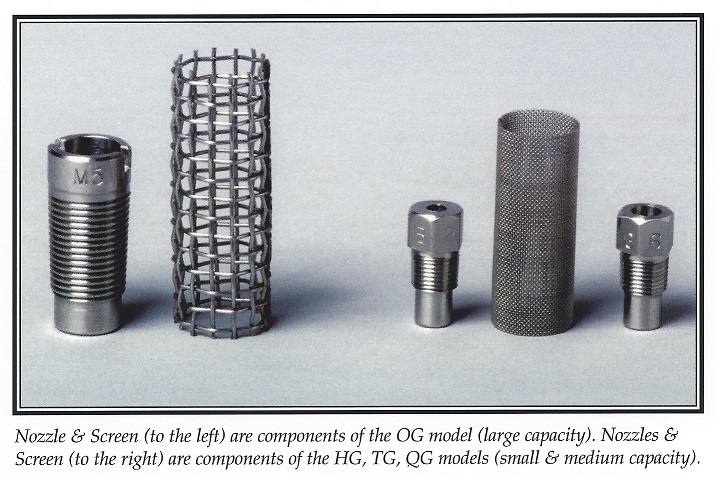

The ProTech steam trap replacement device utilizes an evolved venturi nozzle to serve the function of the orifice plate.

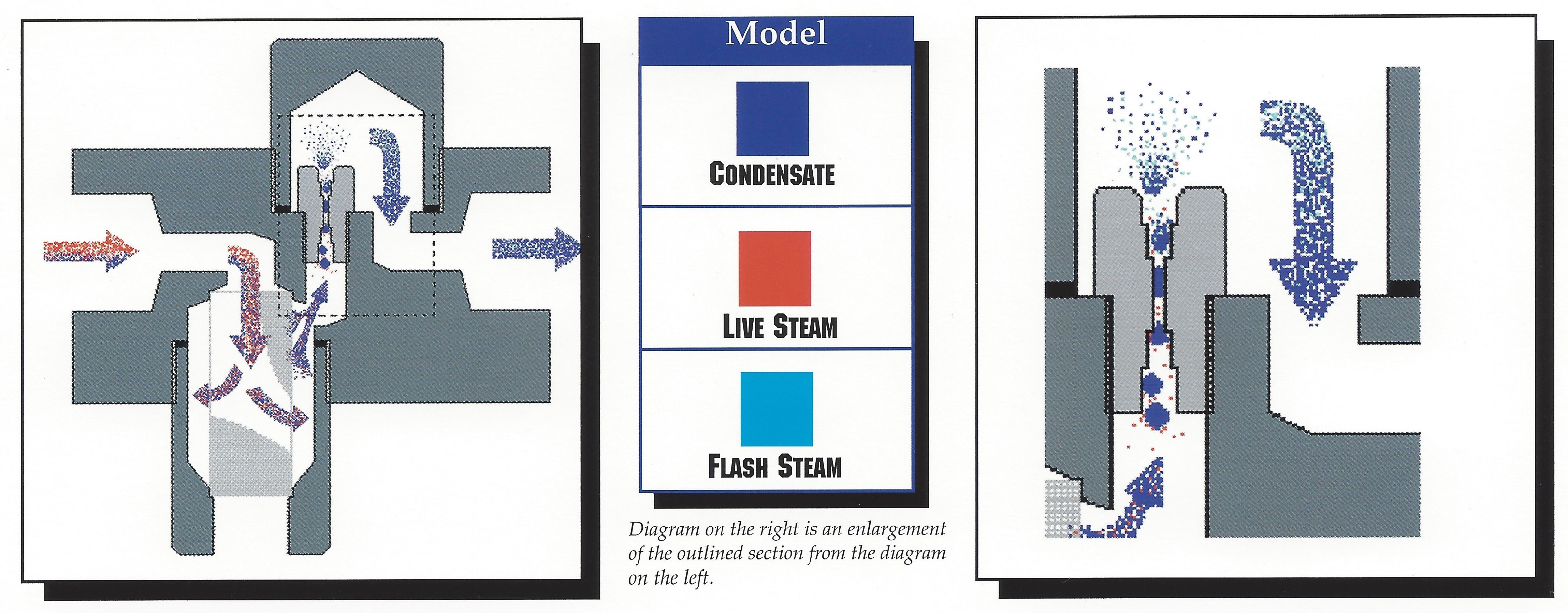

Both the orifice plate and the advanced venturi nozzle serve as an efficient condensate removal device (steam trap) by taking advantage of the significant physical differences (specific volume) between steam and condensate. For example, at 50 psia, steam has a specific volume 500 times greater than that of condensate. The theory of two-phase flow explains condensate’s disruptive impact on the flow of steam. The condensate, denser and traveling at much slower speeds than live steam, occupies the orifice or venturi nozzle and impedes the passage of steam. As condensate exits the diverging section of the venturi nozzle, a portion will flash, resulting in a significant increase in specific volume thus creating a choking effect which further inhibits the passage of live steam.